-

0769-38866368

LVDS Cable for LED Display

PRODUCT PARAMETERS

- Physical form: FFC with a locking FPC connector (typical pitch: 0.5mm/1.0mm), enabling space-saving routing in tight device interiors.

- LVDS optimization: Supports LVDS signal transmission (e.g., video/data signals between motherboards and displays) with low EMI (electromagnetic interference) and stable differential signal integrity.

- Common configurations: Available in pin counts like 10P/14P/20P (matching single/dual LVDS channel requirements) and lengths ranging 50–300mm (suited for short-distance LVDS signal routing inside devices)

Description

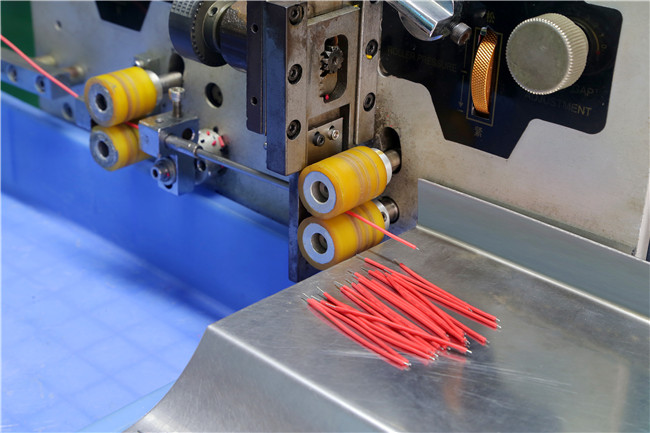

This harness is an LVDS (Low-Voltage Differential Signaling) FFC (Flexible Flat Cable) assembly—a compact, high-speed signal transmission solution commonly used in electronic devices (e.g., display panels, industrial controllers, medical equipment).

FAQs

We have been supplying cable assembly solutions for almost any application since we launched. We engineer and produce cable assemblies to carry power, control signals, communications, date pulses or any combination of these, which including Green energy wire harness, Defence & Industry wire harness, Electrical wire harness, Automotive Wiring Harness, Custom wire harness etc.

Customers can specify the freight forwarder. Usually sent by DHL, FedEx, UPS

We provide customized services. You can provide samples or technical parameters to help us draw drawings for you.

Send Drawing / Requirements

Engineering Assistance—Since most of the cost decisions are made during the design phase, we can help you make component choices to limit future cost issues.

Rapid Prototyping (3-7Days)—Our teams will respond quickly and closely with you, your team, and your project to help you optimize the form, fit, and function of your harness or cable assembly. They will also make you aware of opportunities to reduce costs, while still achieving comparable or greater quality.

Sample Approval

Mass production

Quality Inspection & Delivery

Whether in terms of application, function, construction type, material selection or connection method, customized wiring harnesses can provide targeted solutions to meet special working environments and performance requirements.