-

0769-38866368

Professional Robot Display Wire Harness: Injecting Agile “Vessels” into Intelligent Partners

Robot Display Wiring Harnesses: Infusing Intelligent Partners with Agile “Pathways”

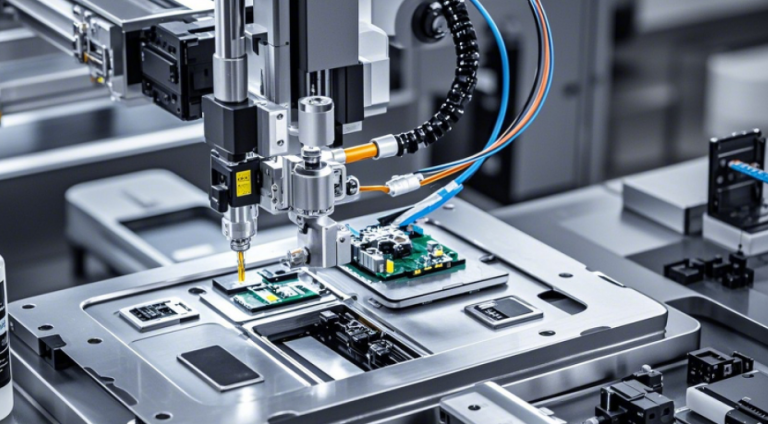

In today’s rapidly advancing technological era, robots have transitioned from science fiction to reality, widely applied across industrial production, logistics delivery, medical care, home services, and many other fields. They have become a key force driving transformation and progress across industries. Within the intricate and sophisticated “bodies” of these robots lies a critical yet often overlooked component — the display wiring harness. Like the “nervous system” of a robot, it undertakes the vital tasks of information transmission and command interaction, serving as one of the core elements ensuring efficient operation and precise task execution.

I. Wiring Harnesses — The “Agile Pathways” of Robots

Robot display wiring harnesses are far from simple collections of ordinary cables. Instead, they are complex systems composed of wires, terminals, connectors, protective sleeves, and other precision components, scientifically designed and meticulously manufactured. Their core functions span two critical areas: power transmission and signal delivery.

On one hand, they act as energy conduits, reliably delivering stable power to the robot’s display and related electronic components, ensuring clear screen performance and smooth operation of all functions. On the other hand, as information highways, they accurately transmit command signals from the robot’s control system and feedback status from the display, enabling the robot to adjust its actions in response to environmental changes and interact efficiently with the outside world.

Given the diverse and challenging working environments of robots — from industrial settings with high temperatures, high pressure, and severe electromagnetic interference, to humid and dusty logistics warehouses with high collision risks, to medical facilities demanding utmost safety and stability — display wiring harnesses must meet extremely rigorous performance requirements. A high-quality robot display wiring harness must possess:

- Exceptional flexibility to withstand frequent twisting and stretching during robot movement;

- Outstanding abrasion resistance to endure friction and wear in complex environments;

- Superior anti-interference capabilities to ensure accurate and stable signal transmission even in strong electromagnetic environments, preventing signal distortion or interruption and guaranteeing consistent robot performance.

II. Our卓越 Solutions

As a leading expert with years of deep experience in robot display wiring harnesses, we leverage robust technical expertise, advanced production processes, and an unwavering commitment to quality to provide comprehensive, customized, high-quality wiring harness solutions that help unleash the full potential of various robots.

(一) Customized Services Tailored to Diverse Needs

We understand that display wiring harness requirements vary significantly across different robot applications. Our professional R&D team works closely with clients to thoroughly understand their robot design architecture, operational environment, and specific functional requirements. Every detail — from harness length, wire gauge, and conductor material selection to connector types, interface configurations, and overall wiring layout — is tailored to meet client needs. Whether addressing industrial robots’ demands for high-load power transmission and high-speed signal processing, service robots’ need for lightweight and flexible harness designs, or special-purpose robots’ stringent requirements for extreme environment protection, we deliver precisely matched, customized solutions.

(二)卓越 Performance Ensuring Reliable Quality

- High Flexibility & Bend Resistance: We use high-purity oxygen-free copper as the core conductor material, combined with advanced stranding techniques, to ensure exceptional harness flexibility. This allows the harness to easily adapt to complex robot movements, significantly reducing the risk of conductor breakage from frequent bending. Rigorous testing shows our harnesses withstand millions of bending cycles, far exceeding industry standards, greatly extending service life and minimizing downtime due to harness failures.

- Excellent Anti-Interference Capability: For critical signal transmission segments, we employ a dual-layer shielding structure — an inner layer of high-conductivity tinned copper braid and an outer layer of aluminum foil mylar tape — providing dual protection against electromagnetic interference. Optimized structural design and wiring further reduce impedance variations during signal transmission, ensuring integrity and stability. This enables robot displays to present information accurately in real time, supporting precise robot operations.

- Superior Environmental Adaptability: To address various harsh working conditions, we prioritize material selection and protective processes. For high-temperature environments, we use high-temperature-resistant insulation and sheathing to ensure performance at up to [X]°C. In humid or dusty settings, specialized waterproof and dustproof designs achieve IP [X] ratings, effectively resisting moisture and dust ingress. For chemically corrosive environments, corrosion-resistant materials ensure long-term stability.

(三) Stringent Quality Control Ensuring Zero-Defect Delivery

Quality is our cornerstone. We implement a comprehensive, end-to-end quality management system throughout the production process. This includes:

- Strict screening and inspection of raw materials, ensuring all wires, connectors, and other components meet the highest industry standards;

- Meticulous process management with rigorous quality checkpoints at every stage, combining advanced automated detection equipment with manual sampling to evaluate electrical performance, mechanical properties, and appearance;

- Final inspection and packaging where every harness undergoes rigorous testing to ensure zero-defect delivery.

Our relentless efforts keep product defect rates exceptionally low, earning us high trust and recognition from clients.

III. Advancing Together, Creating an Intelligent Future

As robot technology evolves and applications expand, we remain committed to the principles of “professionalism, innovation, quality, and service.” We are dedicated to providing global clients with the finest robot display wiring harness products and solutions. We invite robot manufacturers, system integrators, and industry partners to join us in exploring innovative applications, enhancing product performance and quality, and contributing to the thriving development of the robot industry.